Magnetic Particle

Magnetic Particle Testing (MT) is the use of magnetism, and finely divided magnetic particles that are attracted to any surface or near surface flaw on a material when the material is magnetized. (useful on ferromagnetic materials only) Inspection particles can be in a wet fluorescent suspension or dry visible particles of any color that contrasts with the background color of the material.

Visible Dry

Particles start out as tiny milled pieces of iron or iron oxide. A pigment is bonded to their surfaces to give the particles color. The metal used for the particles has high magnetic permeability and low retentivity. High magnetic permeability is important because it makes the particles attract easily to small magnetic leakage fields from discontinuities, such as flaws.

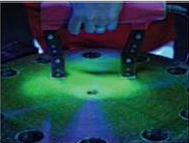

Wet Fluorescent

The presence of a surface or subsurface discontinuity in the material allows the magnetic flux to leak, since air cannot support as much magnetic field per unit volume as metals. Ferrous iron particles are then applied to the part. The particles may be dry or in a wet suspension. If an area of flux leakage is present the particles will be attracted to this area. The particles will build up at the area of leakage and form what is known as an indication. The indication can then be evaluated