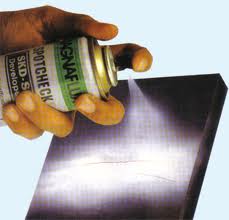

Liquid Penetrant

Liquid Penetrant Testing (PT) involves the use of a fluorescent or brightly colored visible liquid applied to the surface of a test article to penetrate flaws open to the surface, then removing all excess liquid and applying a developer to cause any liquid trapped by a flaw to bleed and become visible identifying the presence and extent of possible flaws.

Visible Dye or Fluorescent Dye

Penetrant inspection is only useful for detecting flaws open to the surface, but is the most sensitive inspection method for surface flaws. Visible and fluorescent penetrant can be used depending on specification requirements. Penetrant removal is performed with either solvent dampened wipes or washed with controlled pressure/temperature water. Developer used to bring out any penetrant trapped by a surface irregularity is typically non-aqueous wet aerosol type developer.